Noisy Oven? Strange Sounds & Noise Repair Guide Toronto

Unusual noises from your oven can indicate various mechanical or electrical issues that need attention. From clicking and buzzing to grinding and rattling, different sounds point to specific problems. Here's your comprehensive guide to identifying, diagnosing, and fixing oven noise issues.

Quick Answer: Oven making strange noises, clicking, buzzing, or grinding sounds? Learn to identify and fix oven noise problems. Expert oven repair in Toronto from JK Appliances. This is a common issue that can usually be resolved with proper troubleshooting. If the problem persists, professional diagnosis is recommended.

Common Oven Noises and Their Meanings

CLICKING SOUNDS

Normal clicking: Gas valve operation, relay switching, thermal expansion Abnormal clicking: Rapid repeated clicking, clicking without function Causes: Faulty relays, gas valve problems, control board issues When to worry: Continuous clicking, clicking with no oven operation

BUZZING OR HUMMING

Normal buzzing: Transformer operation, fan motors, electrical components Abnormal buzzing: Loud buzzing, irregular patterns, electrical arcing Sources: Control transformers, magnetron (microwave combo), loose electrical connections Concern level: Loud or irregular buzzing needs investigation

GRINDING OR SCRAPING

Typical causes: Fan motor bearing wear, convection fan obstruction Severity: Usually indicates mechanical wear requiring attention Components involved: Cooling fans, convection fans, motor assemblies Action needed: Immediate inspection to prevent further damage

RATTLING OR VIBRATION

Common sources: Loose panels, worn fan blades, mounting hardware Impact: Can worsen over time, may indicate loose components Areas to check: Oven racks, door panels, fan assemblies, mounting screws Prevention: Regular tightening of hardware

SQUEALING OR SCREECHING

Primary cause: Motor bearing failure, belt wear (older models) Urgency: High - indicates imminent component failure Components: Fan motors, blower assemblies, drive mechanisms Risk: Complete motor failure if not addressed

Understanding Oven Sound Sources

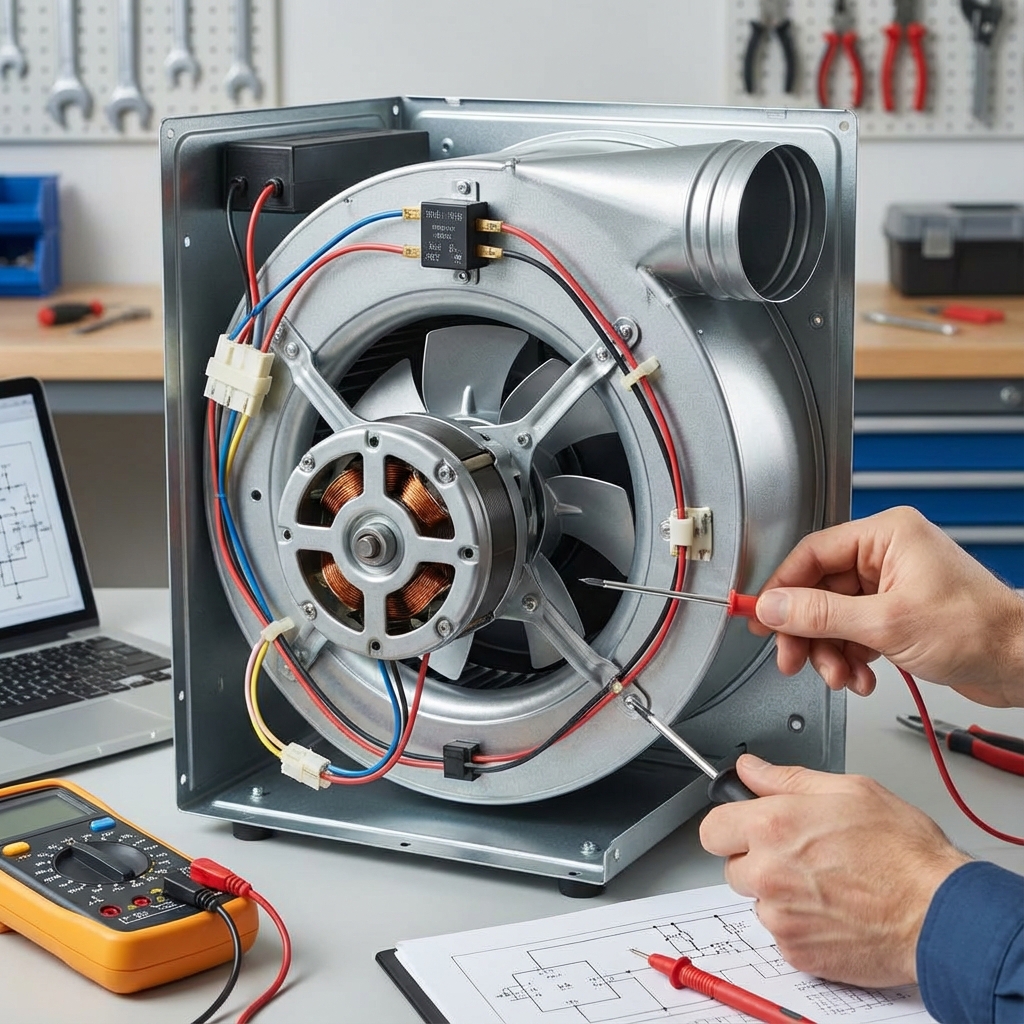

CONVECTION FAN SYSTEMS

Function: Circulates hot air for even cooking Normal sounds: Gentle whooshing, low hum during operation Problem indicators: Grinding, squealing, irregular operation Common issues: Bearing wear, blade damage, motor failure

COOLING FAN SYSTEMS

Purpose: Prevents overheating of electrical components Operation: Runs during and after cooking cycles Normal operation: Quiet, consistent airflow sound Problems: Loud operation, irregular cycling, failure to run

ELECTRICAL COMPONENTS

Relays and contactors: Normal clicking during switching Transformers: Low-level humming is typical Control boards: Should operate silently Warning signs: Loud buzzing, crackling, irregular sounds

MECHANICAL COMPONENTS

Door hinges: Should operate smoothly and quietly Racks and guides: Minimal noise during insertion/removal Thermal expansion: Some clicking/popping during heating is normal Mounting hardware: Should be secure and vibration-free

Diagnosing Noise Problems

SOUND IDENTIFICATION PROCESS

Recording and Timing

- Note when noise occurs - startup, during operation, cooldown

- Record duration - continuous, intermittent, specific cycles

- Document frequency - every use, occasional, specific functions

- Identify triggers - temperature changes, specific settings

Location Identification

- Determine noise source - top, bottom, back, sides

- Use stethoscope or listening device for precision

- Check with oven door open and closed

- Test different operating modes

Operational Testing

- Test all oven functions systematically

- Note noise changes with different settings

- Check during heating and cooling cycles

- Test convection vs. conventional modes

VISUAL INSPECTION

Fan Assembly Examination

- Remove oven racks for clear access

- Inspect convection fan for damage or obstruction

- Check fan blade alignment and condition

- Look for debris or foreign objects

Electrical Component Check

- Inspect visible wiring for damage or looseness

- Check relay and contactor mounting

- Look for signs of electrical arcing or burning

- Verify secure component mounting

Mechanical Assessment

- Check all mounting screws and hardware

- Inspect door hinges and operation

- Test oven rack movement and fit

- Look for loose panels or covers

DIY Noise Troubleshooting

SIMPLE FIXES

Loose Hardware Tightening

- Turn off power to oven

- Check all visible screws and mounting hardware

- Tighten loose connections carefully

- Don't overtighten - can strip threads or crack components

- Test operation after tightening

Cleaning and Debris Removal

- Remove oven racks and accessories

- Clean fan areas of grease and debris

- Check for foreign objects in fan assemblies

- Use compressed air to blow out dust

- Reassemble and test operation

Rack and Accessory Adjustment

- Remove all racks and accessories

- Test oven operation without racks

- Reinstall racks one at a time

- Check for proper fit and alignment

- Replace damaged or warped racks

INTERMEDIATE REPAIRS

Fan Motor Lubrication

- Locate fan motor access points

- Check manufacturer specifications for lubrication

- Use appropriate high-temperature lubricant

- Apply sparingly to bearing points

- Test operation after lubrication

Note: Many modern motors are sealed and don't require lubrication.

Relay Replacement

- Identify faulty relay by sound location

- Turn off power and remove relay

- Test relay with multimeter if equipped

- Replace with exact part number

- Test oven operation

Door Hinge Adjustment

- Remove oven door following manufacturer procedure

- Inspect hinge pins and bushings

- Clean and lubricate hinge points

- Adjust door alignment if necessary

- Reinstall door and test operation

Professional Repair Situations

MOTOR REPLACEMENT

When professional service needed:

- Fan motor bearing failure

- Motor electrical problems

- Complex disassembly required

- Warranty considerations

Why professional needed:

- Specialized tools required

- Electrical safety concerns

- Proper motor selection critical

- System integration testing

CONTROL BOARD ISSUES

Complex noise problems:

- Relay control malfunctions

- Timing sequence problems

- Multiple system integration

- Electronic component failures

STRUCTURAL REPAIRS

Professional expertise required:

- Oven frame modifications

- Major component replacement

- Safety system integration

- Code compliance issues

Common Issues by Oven Brand

WHIRLPOOL/KITCHENAID OVENS

Typical noise problems:

- Convection fan motor wear

- Cooling fan cycling issues

- Relay clicking problems

- Door hinge wear

Common solutions:

- Fan motor replacement

- Relay updates

- Hinge lubrication

GE OVENS

Frequent noise issues:

- Transformer humming

- Fan blade imbalance

- Control relay problems

- Thermal expansion sounds

Repair approaches:

- Component isolation

- Transformer replacement

- Fan balancing

FRIGIDAIRE OVENS

Known noise problems:

- Cooling fan operation

- Convection motor issues

- Electronic control sounds

- Door mechanism wear

Solutions:

- Fan motor upgrades

- Control board updates

- Door hardware replacement

SAMSUNG OVENS

Common noise concerns:

- High-tech component sounds

- Fan speed control issues

- Electronic feedback

- Precision motor operation

Typical fixes:

- Software updates

- Motor calibration

- Component replacement

Safety Considerations

ELECTRICAL SAFETY

- Turn off power before any work

- Don't ignore electrical buzzing sounds

- Check for arcing or sparking

- Call professionals for electrical noise issues

MECHANICAL SAFETY

- Don't operate with obvious mechanical problems

- Secure all loose components

- Don't force stuck mechanisms

- Replace damaged parts promptly

FIRE PREVENTION

- Address electrical noise immediately

- Don't ignore burning smells with noise

- Keep area clear of combustibles

- Monitor operation closely if noise present

CARBON MONOXIDE CONCERNS (Gas Ovens)

- Ensure proper combustion with any noise changes

- Check ventilation systems

- Install CO detectors

- Professional inspection for gas-related noises

Maintenance for Noise Prevention

REGULAR CLEANING

- Monthly deep cleaning of fan areas

- Remove grease buildup that can cause imbalance

- Clean air passages for proper airflow

- Keep electrical connections clean

LUBRICATION SCHEDULE

- Annual inspection of moving parts

- Lubricate hinges as needed

- Check fan bearings for wear

- Follow manufacturer maintenance schedules

HARDWARE CHECKS

- Quarterly tightening of visible screws

- Annual comprehensive hardware inspection

- Replace worn components proactively

- Monitor for new noise development

Toronto-Specific Considerations

CLIMATE EFFECTS

Winter heating: Thermal cycling can cause expansion noises Summer humidity: Can affect electrical components and cause noise Temperature extremes: May stress mechanical components

BUILDING CHARACTERISTICS

Older homes: May have settling that affects oven mounting Condos: Noise transmission concerns for neighbors Kitchen renovations: May affect oven installation and noise levels

SERVICE AVAILABILITY

- Parts availability: Most noise-related components available locally

- Authorized service: Available throughout GTA

- Emergency service: JK Appliances offers prompt noise diagnosis

Cost Analysis

DIY SOLUTIONS

- Basic tools: $30-50

- Cleaning supplies: $10-20

- Lubricants: $15-25

- Hardware replacement: $20-50

PROFESSIONAL REPAIRS

- Noise diagnosis: $100-150

- Fan motor replacement: $200-400

- Control board repair: $250-500

- Complete noise elimination: $300-600

PREVENTION COSTS

- Annual maintenance: $100-200

- Preventive part replacement: $150-300

- Professional inspection: $75-150

Troubleshooting Quick Reference

CLICKING NOISES

- Identify timing - when does clicking occur

- Check relays for proper operation

- Test gas valve operation (gas ovens)

- Inspect control board connections

GRINDING SOUNDS

- Locate fan making noise

- Check for obstructions

- Inspect motor bearings

- Test fan blade condition

BUZZING OR HUMMING

- Determine if electrical in nature

- Check transformer operation

- Inspect electrical connections

- Test under different loads

RATTLING OR VIBRATION

- Check all mounting hardware

- Inspect oven racks and accessories

- Test door operation

- Look for loose panels

When to Call Professionals

IMMEDIATE SERVICE NEEDED

- Loud electrical buzzing or crackling

- Grinding sounds from motors

- Safety concerns with operation

- Multiple noise sources

COMPLEX NOISE ISSUES

- Intermittent problems

- Multiple system involvement

- Electronic control related noises

- Warranty considerations

SAFETY-CRITICAL SITUATIONS

- Electrical arcing sounds

- Gas-related noise changes

- Structural integrity concerns

- Fire or shock hazards

Prevention Strategies

PROPER USAGE

- Don't overload oven racks

- Avoid slamming doors

- Keep oven clean to prevent buildup

- Follow manufacturer guidelines

REGULAR MAINTENANCE

- Clean regularly to prevent debris buildup

- Lubricate moving parts as recommended

- Tighten hardware periodically

- Monitor for early noise signs

ENVIRONMENTAL CONTROL

- Maintain stable kitchen temperature

- Control humidity levels

- Ensure proper ventilation

- Protect from vibration sources

FAQ

Q: Is it normal for my oven to make clicking sounds? A: Some clicking is normal during operation (relays, thermal expansion), but continuous or loud clicking needs investigation.

Q: Why does my convection oven make a humming sound? A: Normal operation includes fan motor humming. Loud or irregular humming may indicate motor problems.

Q: Should I be concerned about grinding noises from my oven? A: Yes, grinding usually indicates mechanical wear and should be addressed promptly to prevent further damage.

Q: Can I continue using my oven if it's making strange noises? A: Depends on the noise type. Electrical buzzing or grinding sounds should be investigated immediately.

Q: How can I tell if oven noise is serious? A: Loud, irregular, or new noises warrant investigation. When in doubt, have it professionally diagnosed.

Don't let noise problems disrupt your cooking! JK Appliances provides expert oven noise diagnosis and repair throughout Toronto. Our technicians quickly identify and resolve all types of oven noise issues. Call (647) 560-8966 or book online for quiet, reliable oven operation.

Common Questions People Ask

Q: Is it normal for my oven noise problems to have issues? No, this is not normal behavior and indicates an underlying issue that should be addressed promptly to prevent further damage.

Q: Can I fix this oven noise problems problem myself? Some basic issues can be resolved with DIY troubleshooting, but complex problems require professional diagnosis to avoid safety risks and warranty issues.

Q: How much does professional oven noise problems repair cost in Toronto? Repair costs typically range from $150-$400 depending on the specific issue and parts needed. Our technicians provide free estimates before any work begins.

Q: How long does oven noise problems repair take? Most repairs are completed within 1-2 hours during a single visit. Some cases may require ordering specialty parts with a follow-up appointment.

Q: Should I repair or replace my oven noise problems? If your oven noise problems is less than 8 years old and repair costs are under 50% of replacement cost, repair is usually the better value. Our technicians can help you make the right decision.

Q: Do you offer same-day oven noise problems repair in Toronto? Yes! We offer same-day and emergency repair services throughout Toronto and the Greater Toronto Area for urgent issues.

Q: What brands of oven noise problems do you repair? We service all major brands including Bosch, Samsung, LG, Whirlpool, KitchenAid, GE, Maytag, Frigidaire, Miele, and more.

Q: Is oven noise problems repair covered by warranty? Many oven noise problems issues are covered under manufacturer warranty. We can help verify your warranty status and handle claim processing.

Expert Tips & Pro Insights

💡 Pro Tip: Regular maintenance can prevent 80% of appliance problems. Follow manufacturer guidelines for cleaning and care.

⚠️ Safety Warning: Always disconnect power before attempting any repairs or inspections. If you smell gas, evacuate immediately and call emergency services.

🔧 Technician Insight: Many issues that seem complex often have simple solutions. Start with basic troubleshooting before assuming the worst.

📞 When to Call a Professional: If you encounter electrical components, gas lines, refrigerant systems, or if basic troubleshooting doesn't resolve the issue, it's time to call an expert.